Day 2 of the rebuild of the big Yak. Where were we? Oh yes, adding more pieces to make a pile of wood into a flying airframe. LOL. I didn't get started as early this morning as I did yesterday. But still got quite a bit accomplished. I had to swing by Hobby Town for some 1/8" x 1/8" stringers. I had inadvertently forgot to have Tony include them. But I needed more CA any way, so a trip was necessary. I started off by getting some of the stringers set into place. Straight forward as it was, I got that knocked out of the way so I could get things rolling on the rest of the rebuild. I also installed the rear hatch retainer screw plates. I also got the rear vent hatch framed. I will wrap the outer ply skin around it tomorrow once the rest of the fuse is complete. I figure I will need to make some small adjustments to make it slide into position easily. I think it will be much easier once the total airframe is complete so there will be no twisting and everything is straight. I really like this newer design. It was really thought out well for placement of everything.

Next I needed to start assembling the inner fuse side formers. The remaining stringers will rest on these and will need to be in place before the outer fuse sides are installed. I also needed to install the wing socket sheeting rings on the inner and outer fuse sides. These little guys are so very cool. Slide them under the side formers, glue into position and then the sheeting for the wing sockets slide in to create a clean and neat wing socket.

Once the sheeting rings were tac glued into place, I used my wing panel to double check clearance all the way around the wing. I would have really been mad if the wings had not seated correctly and had the correct spacing for the sheeting that will be glued in once the outer fuse sides are installed. With the clearance checked, the wing panels were set off to the side for later fit.

Next up... the outer fuse sides with the wing socket sheeting retainer rings. Pretty easy here too. Just a dab of CA every couple of inches is more than enough to old them in to their proper location.

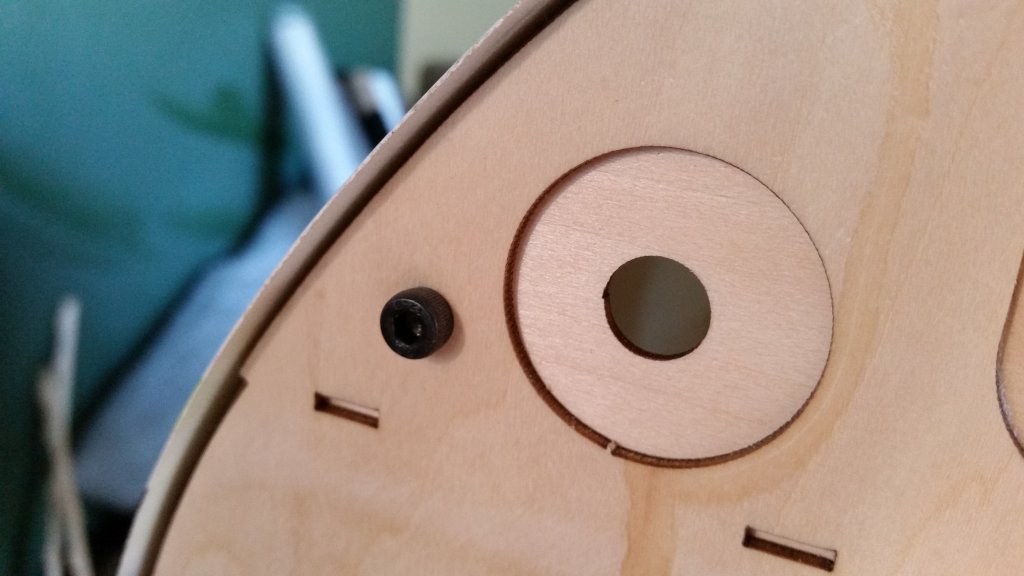

I felt now was a good time to do a canopy test fit to make sure everything was aligning correctly. The canopy retainer rings in the front former..."F1" are pretty snug. This is going to be pretty cool. Everything is fitting together quite nicely with a very snug fit. Just like a brand new airframe. I also figured now would be a good time to get the cowl retainer blind nuts set. Once the rest of the stringers are placed and the front fuse sheeting is layed down, it will be virtually impossible to get the lower cowl retainer blind nuts in place. Hey, she is starting to look like a plane again. LOL

Ok...time to start getting the backing straps in place. These dudes stretch from the front former "F1" back to mid ship. They are responsible for giving support for the outer fuse sides. I as actually pretty pleased with myself. Not having a jig or anything to go by other than just gluing pieces into place, I was worried that everything would not come back into the correct location. My fears were calmed however once the outer fuse backing strap was glued into place. Man, it fit like a perfect hand in glove. The zig zag "W" cut of the front section and rear section matched perfectly. This is the joint location where the front and rear fuse sections come together.

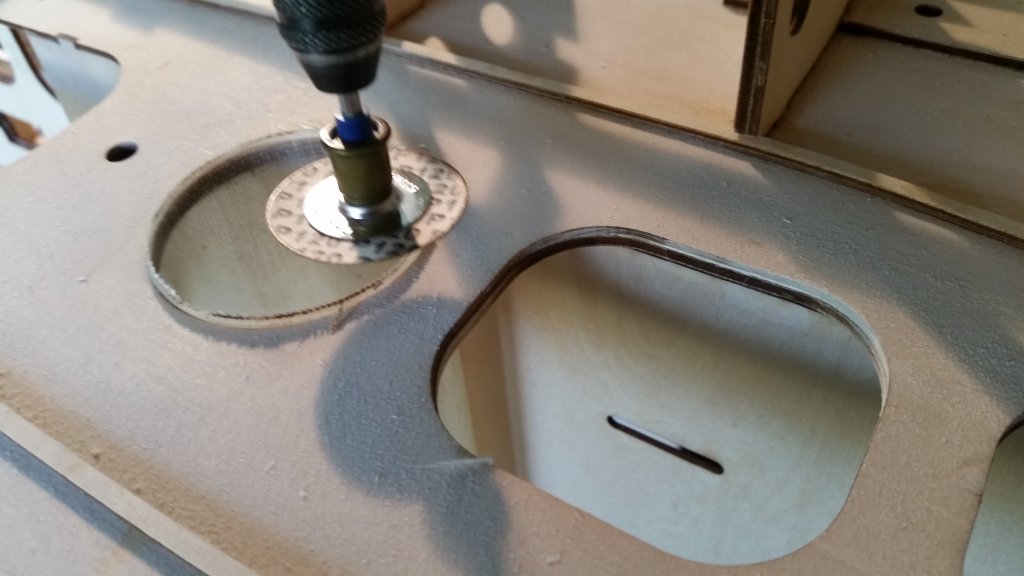

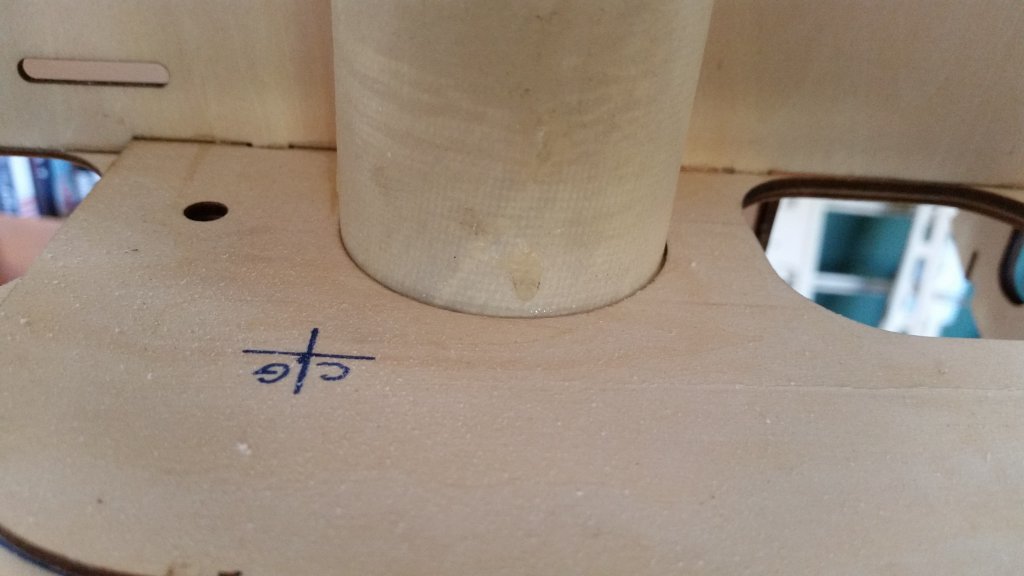

Ok, so before we go further, the installation of the wing tube sleeve should probably be put in. I mixed up some epoxy for this step. I figured that 15 minute would work great for this step. By installing the sleeve through the wing tube holes nearly all the way so one side was almost flush with the outside of the inner fuse side. I "battered" up the wing tube sleeve on the "inside" of the use on one side and the outside of the sleeve on the opposite side of the fuse. This way I could slide the sleeve into position and it would be pretty much equal across the fuse. Once the epoxy had cured enough to work with, I used a cut off wheel on my dremel and sliced the excess of the sleeve off leaving only about a 1/4" or so protruding on both sides of the fuse. After I had the excess rings removed, I used a sanding disk on my dremel then completed the sanding with a "T" bar sander to flush the sleeve with the outsides of the inner fuse sides. I also double checked my work by sliding the wing tube through the sleeve to test fit. Nice snug fit. Not too loose, not too tight. Just right.

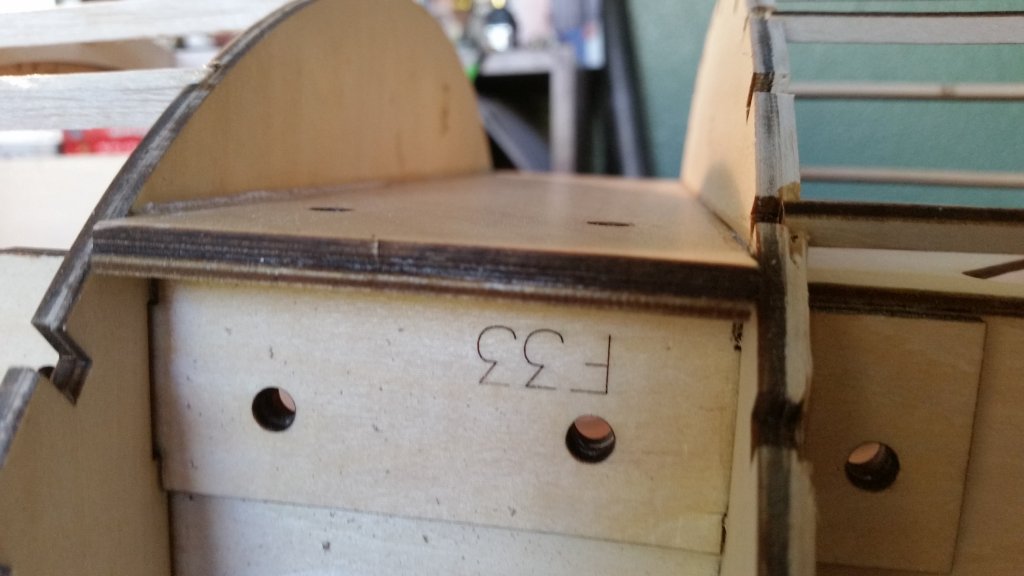

I almost screwed up. I had meant to install the fuse side blind nuts for the landing gear aluminum "L" brace into "F33" before they were installed. Fortunately there was enough room to use my 5 pound solid iron block on the inside of the canister tunnel while I tapped the blind nuts into position from the outside. Worked slick. Whew...I would have hated myself if I had forgotten this step. I also needed to sand a bevel in the laminated landing gear plate to match the shape of the fuse.

Ok, that being done, I proceeded to attach the upper fuse side formers to the top fuse former canopy rest plate. Like the rest of the fuse parts, it is keyed for correct location. It would be almost impossible to mess this step up.

With the bottom of the fuse pretty much complete, the top fuse former canopy rest plate and the fuse side formers in place, I can now start installing the outer fuse side. This will be the tell-tale of all my assembly work. If it matches up with all the keys on the side formers along with everything else, the end result should be a straight and true fuselage.

And here we have the left side outer fuse side in place. Locating and locking keys makes this step really easy. Except gluing it into place. Lots of joints to make sure the glue gets into. But the end result is a nice piece of work.

Other than wing socket sheeting, the left side of the fuse is complete. I will wait to install the sheeting until the rest of the fuse is complete. I will start tomorrow with getting the right side outer fuse side glued into position. It won't be long now before she is ready for new covering. Dang, I have to say....she is looking pretty sweet. I do love the smell of a brand new airframe. Not all of it is new, but enough of it is that it gives my house that new airplane aroma.

More to come to tomorrow. Stay tuned for the rest of the rebuild.

. Keep up the AWESOME work.

. Keep up the AWESOME work.