GSNadmin

Staff member

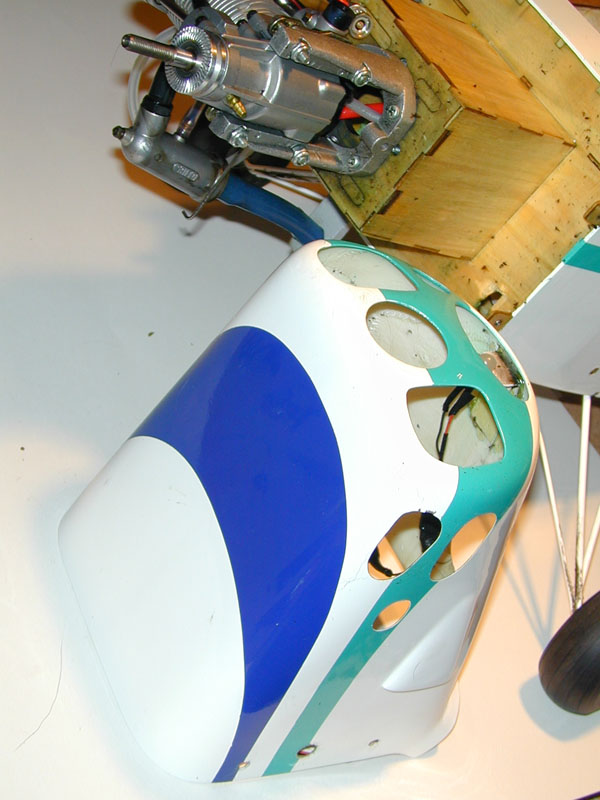

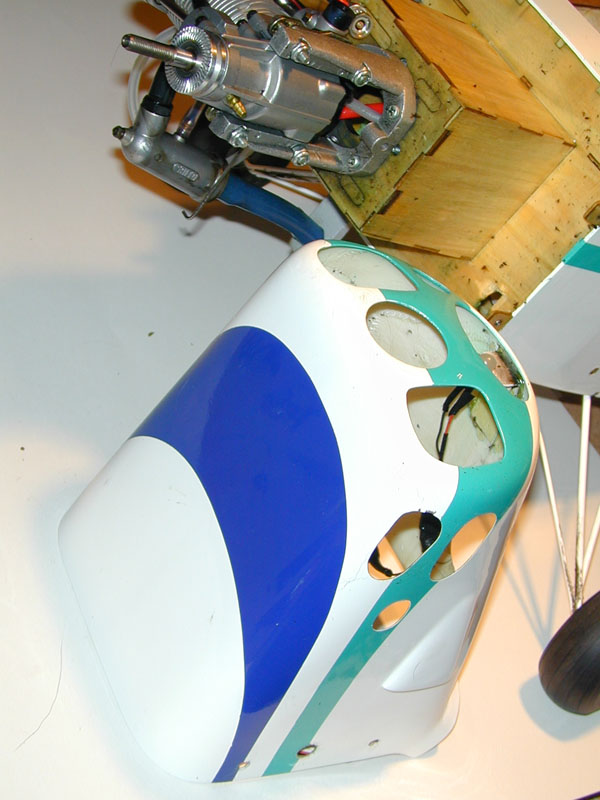

The great thing about almost ready to fly airplanes is that for the most part, they come with great looking fiberglass engine cowls that fit beautifully and often are painted at the factory. The general method of attachment to the fuselage is the use of through-the-cowl screws making assembly quick and simple. After time however, as you build up flight time, engine vibration and everyday knocks and dings will take their toll and our once shiny engine cowl will start to show its age. Of course if one is available, you could simply replace your old engine cowl with a new one, but that’s going to cost you at least 20 bucks not including postage and handling. A great way to save that cash and apply it something you really need, like a gallon of fuel or a new servo, is to repair your cowl by yourself. Here’s how I did it for my Hangar 9 Piper Pawnee crop-duster ARF. It is a variation of the full-size repairs we made in the USAF when I worked on fiberglass radomes, flat panels and nose cones.

1.

Here’s some of the basic tools and materials you’ll need to fix a cracked and worn-out engine cowl. You’ll need fiberglass cloth, Z-poxy Finishing resin, mixing cups and mixing sticks, masking tape, sandpaper, and a Dremel Moto-Tool with some Robart medium grit Carbide grinding bits. You’ll also need some tack cloths, a bottle of spray cleaner, acetone or MEK solvent, denatured or Rubbing alcohol, and some paper towels. You’ll also need a clean place to work and it helps to place some old newspaper or brown wrapping paper to protect your work surface.

2.

Start by carefully removing the old engine cowl from your airplane. If some cracked or broken cowl parts fall away, be sure to save them. Set the rest of the model aside so you don’t get any epoxy resin on your model or the engine.

3.

Thoroughly clean the engine cowl using some spray cleaner inside and out. To really degrease the surface of a very old and greasy fiberglass cowl use Acetone or MEK solvent. Use a paper towel and wipe the cowl down, then go over it again with the solvent to really get the oil and grime removed. If you don’t start with a squeaky-clean surface, your repair won’t adhere properly.

4.

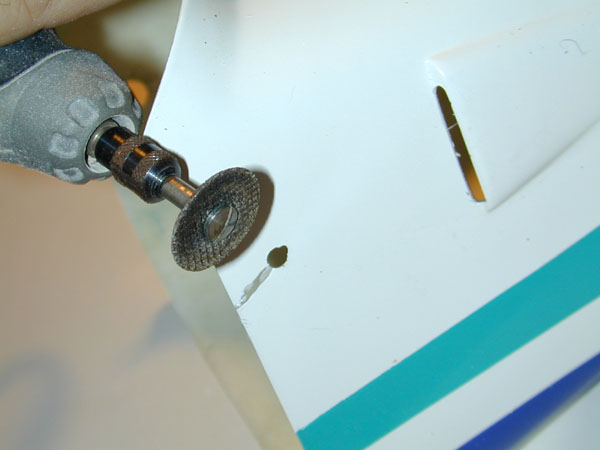

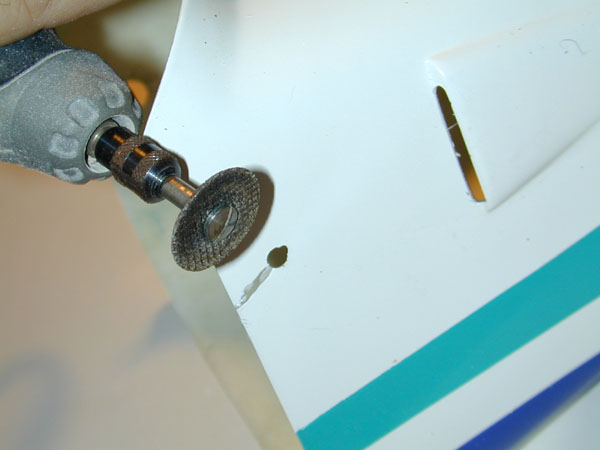

Inspect the cowl and indentify any cracks and damage you want to fix. The first thing you should do whenever you find a crack is to stop-drill it to stop it from spreading. Cracks are formed by stress and stress in a material always looks for the path of least resistance. Sharp corners and jagged holes and cutouts in cowls are where they pop up. When there is a sharp angle in an edge it causes a stress riser which concentrates the forces until a crack forms. When you drill a hole at the end of a crack, you show down its progression by spreading out the area the stress is acting on. So, whenever you see a crack, repair it as soon as possible so it won’t spread.

5.

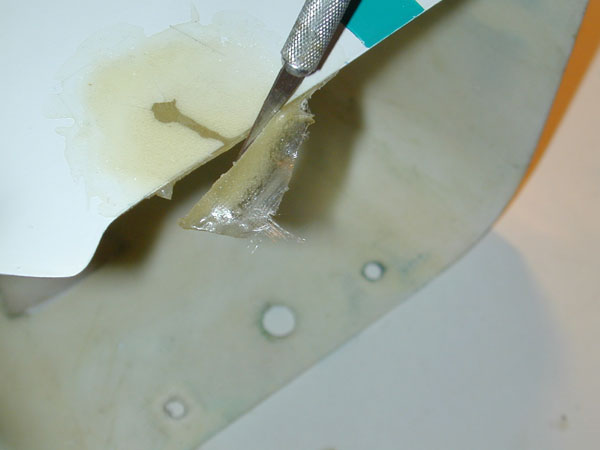

For some damage that happens from vibration and metal parts rubbing against the fiberglass (such as m

ufflers,) the best way to repair and prevent the damage from spreading, is to simply use a grinding bit or cutoff wheel and enlarge the opening by removing the damaged portion. You can see this damage easily with its fractured gel coat and black grease deeply embedded in the edges of the fiberglass. After you degrease the area use a fine tip felt pen and mark the material you’ll remove.

6.

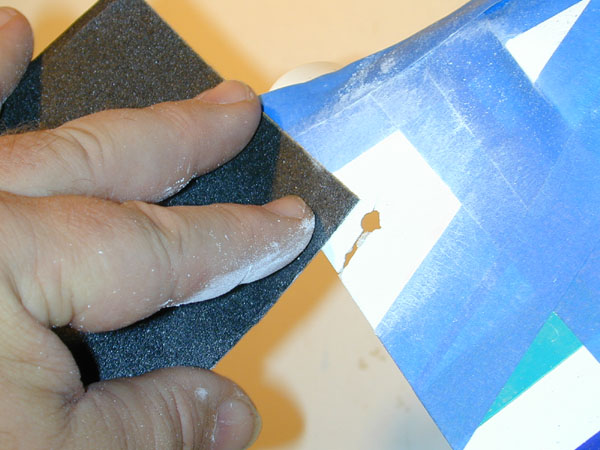

Slowly grind away the material up to the pen mark then use some 220 grip sandpaper and smooth the edges of the opening so there are no more sharp edges to encourage further cracking. You can leave the edges as is, or you can lightly spray with a primer and then shoot a coat of matching color paint to seal the edges. This will help minimize future grim and oil from embedding itself into the fiberglass.

7.

For holes that have cracked out to an edge, like where there attachment screws hold the cowl, you should use a cutoff wheel and lightly remove the very edges of the crack to expose new, clean material. On the inside surface use a grinding wheel to remove a thin portion of the fiberglass and then go over the area with some 220 grit sandpaper to expose clean material for the repair to stick to.

8.

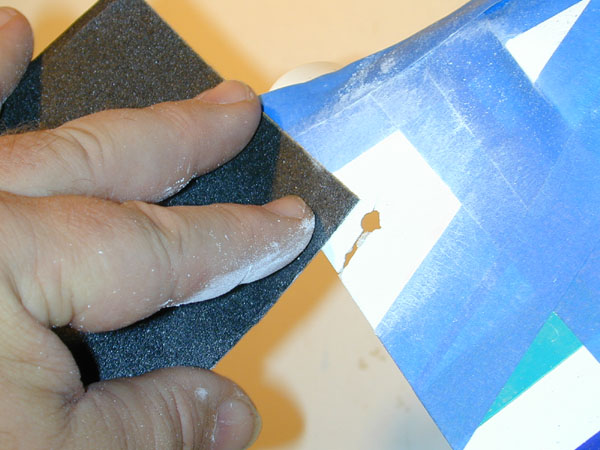

On the outer surface of the cowl, mask off the repair area so you can protect the undamaged finish. Use 220 grit sandpaper and go over the repair area and expose fresh gel coat and fiberglass. Wipe the inside and outside of the repair area and swipe it with a tack cloth to get all the ground fiberglass powder up and away.

9.

/P>

/P>

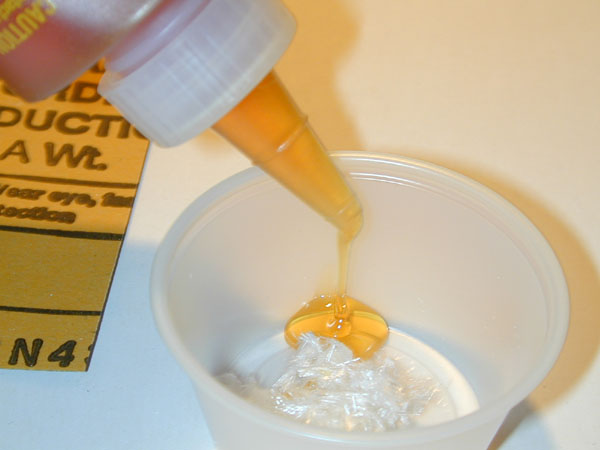

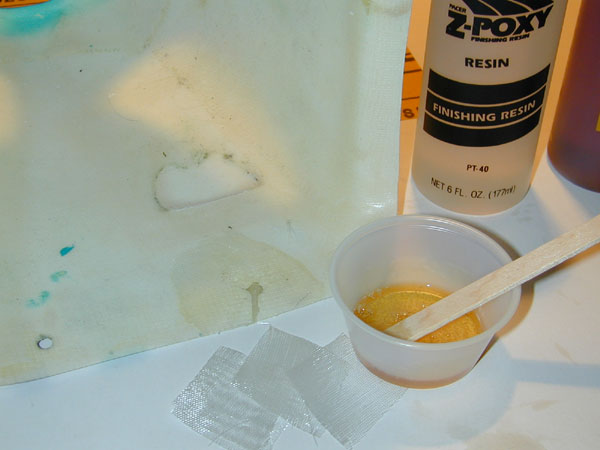

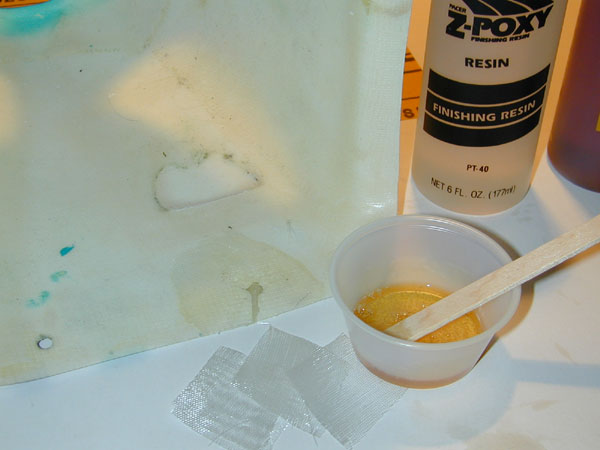

Take some fiberglass cloth, roll it up and then with a sharp pair of scissors cut it into shreads. Do this over some paper and cut the cloth over and over again until you end up with very fine shards of fiberglass. This will be used as a thickening material and will be mixed into the epoxy resin.

10.

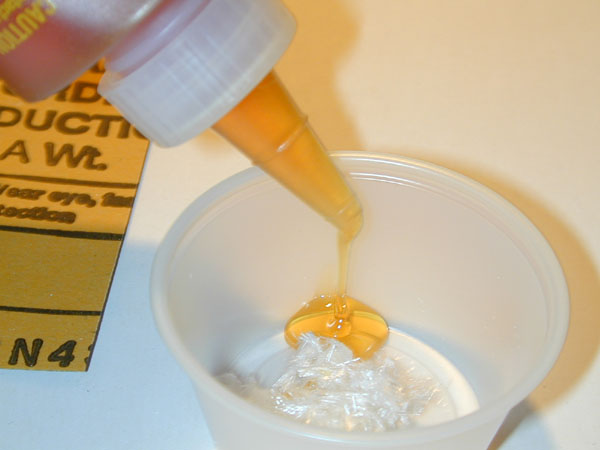

Place the fiberglass shards in a mixing cut and slowly add the finishing resin till you have a 50:50 mixture of resin (both parts A & B) and the filler material. Use a mixing stick and really combine the mixture until it is slightly stiff and strings when you lift the stick from the mixture.

11./o >

>

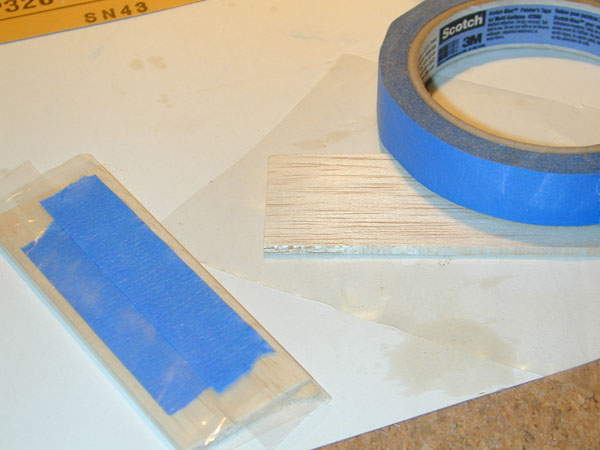

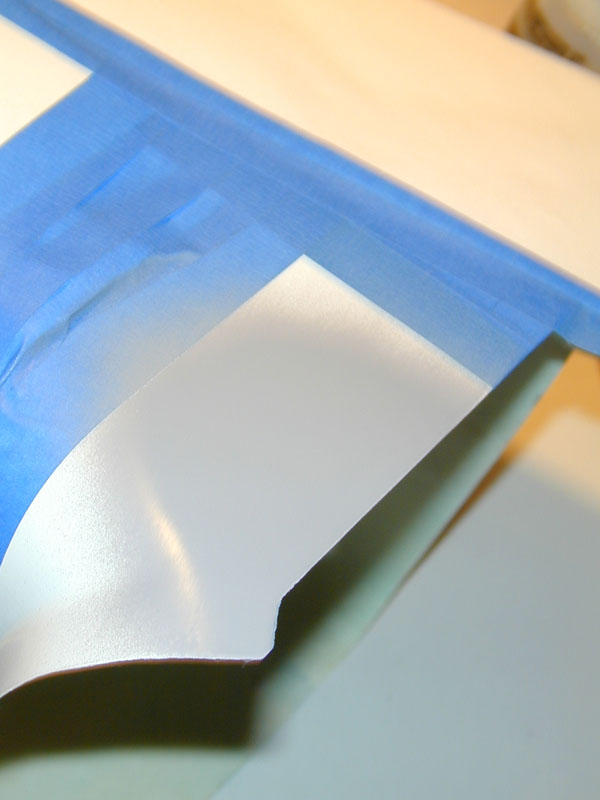

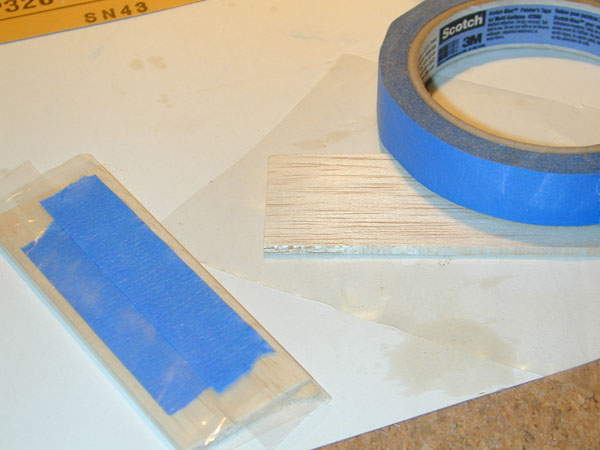

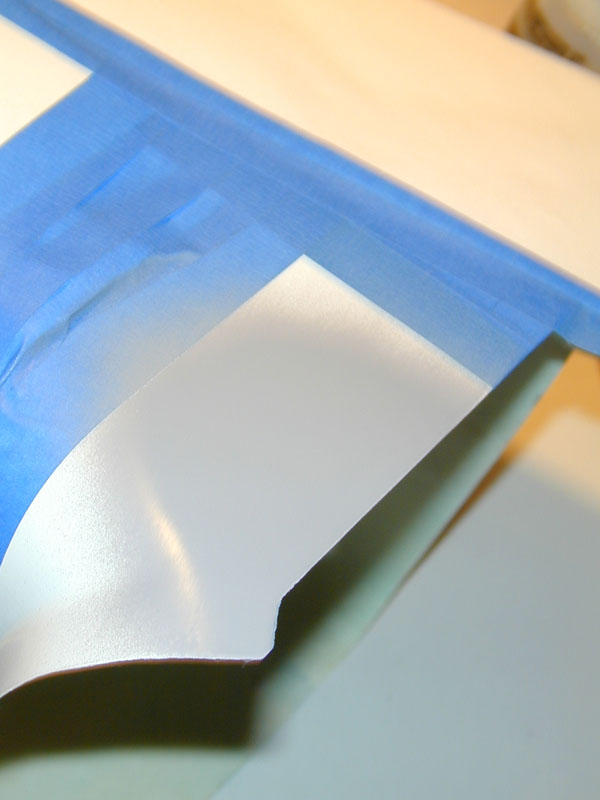

To make the repair build up really smooth, make two backer sheets from balsa wrapped with some MonoKote clear backing, or Great Planes Plans Protector sheeting. Use some tape to hold it in place around the balsa sheets.

12.

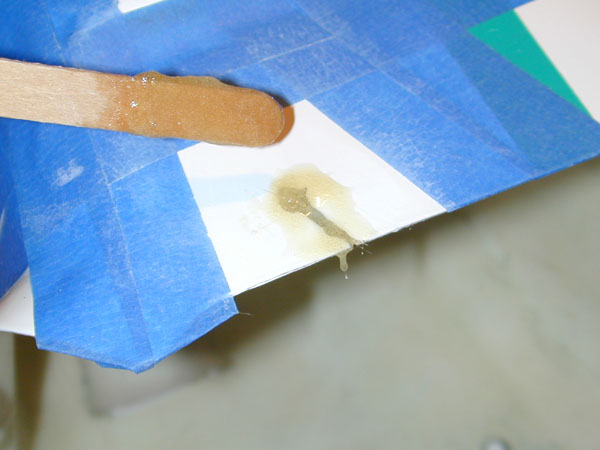

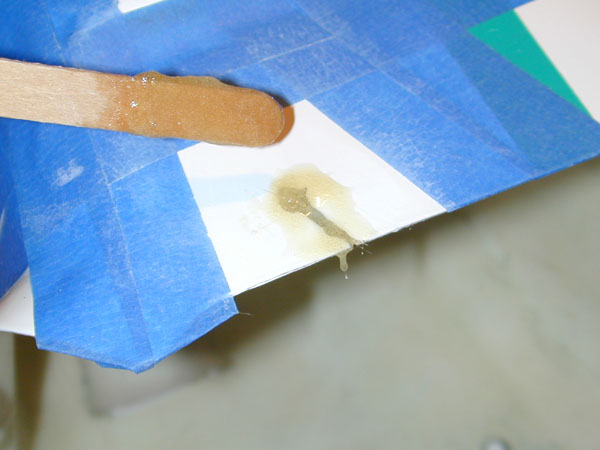

Apply a small glob of resin/filler mixture on the outside of the cowl repair area. Make sure to get the mixture to flow into the hole and crack. keep the amount of filler on the outside surface to a minimum.

13.

Turn the cowl over and place it on top of one of the backing strips. Use a weight to hold the cowl down snuggly over the backing strip and apply more filler material over the inner repair area.

14.

Place the second backing strip over the repair and press down firmly to spread the mixture out. Place the weight on top of the strip and set aside until the repair mixture has set. (30 minutes to 1 hour depending on your brand or resin.)

15.

Here’s what the repair looks like after the backing strips are removed. But you’re not done yet!

16.

Cut 3 or 4 patches of medium weight woven cloth into square patches. The should be an inch all around larger than the repair area. Mix up some more resin and apply the patches over the repair.

17.

Apply patch material to both the inside and outside of

the engine cowl, cover with the release plastic and squeegee out the resin to make a smooth flow of resin. Set aside to set up.

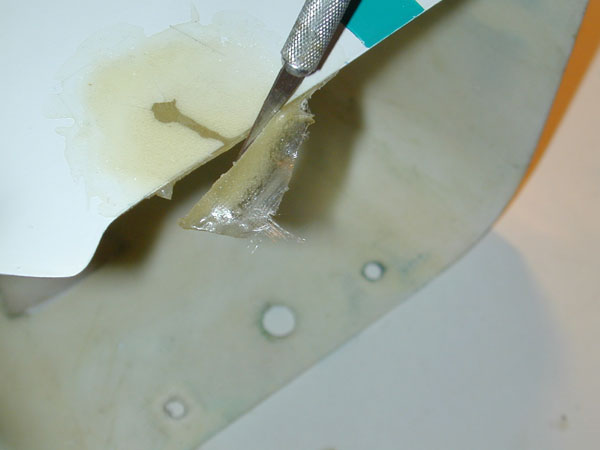

18.

When the resin has cured, remove the release sheet and trim the repair material flush with the edge of the cowling. While the repair material is not completely set up it can be easily cut with a sharp hobby knife. Cut the access material away and then let fully cure before you sand the surface and edge smooth with sandpaper.

19.

Now to make the repair literally disappear, sand the resin and feather it out to the surrounding surface. Use some model filler to fill any pinholes or defects and sand smooth.

20.

Mask off the cowl again and hit with a couple light coat of sandable primer and let dry. Repeat the process until the surface is smooth and flaw-free. Spray the area with a couple light coats of paint to match the engine cowl’s color. Let dry.

21.

Reinstall the engine cowl on the model and mark the location for the attachment hole. Remove from the model, drill a pilot hole and then slowly enlarge the hole by using larger and larger drill bits until it is the proper size. Lightly sand the hole to smooth the edges and if you like, add a light clear coat to add an addition layer of protection.

Well, that about it. I hope this How To technique helps you enjoy the hobby a little more while saving some coin. And who doesn’t want to do that?! So what are you waiting for? Go out and take your newly repaired airplane out and do some flying…

http://www.modelairplanenews.com/wp-content/uploads/2016/02/MAN_Button_newsletter_WEB.jpg

http://www.modelairplanenews.com/wp-content/uploads/2016/02/MAN_Button_newsletter_WEB.jpg

Model Airplane News - The #1 resource for RC plane and helicopter enthusiasts featuring news, videos, product releases and tech tips.

Continue reading...

1.

Here’s some of the basic tools and materials you’ll need to fix a cracked and worn-out engine cowl. You’ll need fiberglass cloth, Z-poxy Finishing resin, mixing cups and mixing sticks, masking tape, sandpaper, and a Dremel Moto-Tool with some Robart medium grit Carbide grinding bits. You’ll also need some tack cloths, a bottle of spray cleaner, acetone or MEK solvent, denatured or Rubbing alcohol, and some paper towels. You’ll also need a clean place to work and it helps to place some old newspaper or brown wrapping paper to protect your work surface.

2.

Start by carefully removing the old engine cowl from your airplane. If some cracked or broken cowl parts fall away, be sure to save them. Set the rest of the model aside so you don’t get any epoxy resin on your model or the engine.

3.

Thoroughly clean the engine cowl using some spray cleaner inside and out. To really degrease the surface of a very old and greasy fiberglass cowl use Acetone or MEK solvent. Use a paper towel and wipe the cowl down, then go over it again with the solvent to really get the oil and grime removed. If you don’t start with a squeaky-clean surface, your repair won’t adhere properly.

4.

Inspect the cowl and indentify any cracks and damage you want to fix. The first thing you should do whenever you find a crack is to stop-drill it to stop it from spreading. Cracks are formed by stress and stress in a material always looks for the path of least resistance. Sharp corners and jagged holes and cutouts in cowls are where they pop up. When there is a sharp angle in an edge it causes a stress riser which concentrates the forces until a crack forms. When you drill a hole at the end of a crack, you show down its progression by spreading out the area the stress is acting on. So, whenever you see a crack, repair it as soon as possible so it won’t spread.

5.

For some damage that happens from vibration and metal parts rubbing against the fiberglass (such as m

ufflers,) the best way to repair and prevent the damage from spreading, is to simply use a grinding bit or cutoff wheel and enlarge the opening by removing the damaged portion. You can see this damage easily with its fractured gel coat and black grease deeply embedded in the edges of the fiberglass. After you degrease the area use a fine tip felt pen and mark the material you’ll remove.

6.

Slowly grind away the material up to the pen mark then use some 220 grip sandpaper and smooth the edges of the opening so there are no more sharp edges to encourage further cracking. You can leave the edges as is, or you can lightly spray with a primer and then shoot a coat of matching color paint to seal the edges. This will help minimize future grim and oil from embedding itself into the fiberglass.

7.

For holes that have cracked out to an edge, like where there attachment screws hold the cowl, you should use a cutoff wheel and lightly remove the very edges of the crack to expose new, clean material. On the inside surface use a grinding wheel to remove a thin portion of the fiberglass and then go over the area with some 220 grit sandpaper to expose clean material for the repair to stick to.

8.

On the outer surface of the cowl, mask off the repair area so you can protect the undamaged finish. Use 220 grit sandpaper and go over the repair area and expose fresh gel coat and fiberglass. Wipe the inside and outside of the repair area and swipe it with a tack cloth to get all the ground fiberglass powder up and away.

9.

Take some fiberglass cloth, roll it up and then with a sharp pair of scissors cut it into shreads. Do this over some paper and cut the cloth over and over again until you end up with very fine shards of fiberglass. This will be used as a thickening material and will be mixed into the epoxy resin.

10.

Place the fiberglass shards in a mixing cut and slowly add the finishing resin till you have a 50:50 mixture of resin (both parts A & B) and the filler material. Use a mixing stick and really combine the mixture until it is slightly stiff and strings when you lift the stick from the mixture.

11./o

To make the repair build up really smooth, make two backer sheets from balsa wrapped with some MonoKote clear backing, or Great Planes Plans Protector sheeting. Use some tape to hold it in place around the balsa sheets.

12.

Apply a small glob of resin/filler mixture on the outside of the cowl repair area. Make sure to get the mixture to flow into the hole and crack. keep the amount of filler on the outside surface to a minimum.

13.

Turn the cowl over and place it on top of one of the backing strips. Use a weight to hold the cowl down snuggly over the backing strip and apply more filler material over the inner repair area.

14.

Place the second backing strip over the repair and press down firmly to spread the mixture out. Place the weight on top of the strip and set aside until the repair mixture has set. (30 minutes to 1 hour depending on your brand or resin.)

15.

Here’s what the repair looks like after the backing strips are removed. But you’re not done yet!

16.

Cut 3 or 4 patches of medium weight woven cloth into square patches. The should be an inch all around larger than the repair area. Mix up some more resin and apply the patches over the repair.

17.

Apply patch material to both the inside and outside of

the engine cowl, cover with the release plastic and squeegee out the resin to make a smooth flow of resin. Set aside to set up.

18.

When the resin has cured, remove the release sheet and trim the repair material flush with the edge of the cowling. While the repair material is not completely set up it can be easily cut with a sharp hobby knife. Cut the access material away and then let fully cure before you sand the surface and edge smooth with sandpaper.

19.

Now to make the repair literally disappear, sand the resin and feather it out to the surrounding surface. Use some model filler to fill any pinholes or defects and sand smooth.

20.

Mask off the cowl again and hit with a couple light coat of sandable primer and let dry. Repeat the process until the surface is smooth and flaw-free. Spray the area with a couple light coats of paint to match the engine cowl’s color. Let dry.

21.

Reinstall the engine cowl on the model and mark the location for the attachment hole. Remove from the model, drill a pilot hole and then slowly enlarge the hole by using larger and larger drill bits until it is the proper size. Lightly sand the hole to smooth the edges and if you like, add a light clear coat to add an addition layer of protection.

Well, that about it. I hope this How To technique helps you enjoy the hobby a little more while saving some coin. And who doesn’t want to do that?! So what are you waiting for? Go out and take your newly repaired airplane out and do some flying…

http://www.modelairplanenews.com/wp-content/uploads/2016/02/MAN_Button_newsletter_WEB.jpg

http://www.modelairplanenews.com/wp-content/uploads/2016/02/MAN_Button_newsletter_WEB.jpgModel Airplane News - The #1 resource for RC plane and helicopter enthusiasts featuring news, videos, product releases and tech tips.

Continue reading...