Len

30cc

Hi guys,

I'm new to this site and thought I'd share with you some modification we've done to the Hempel 38% Decathlon over the last few years.

We use the Decathlon as a front line tug for aerotowing, (www.RcAerotowing.com/forum) and most of the modifications were done to make the plane ultra reliable and easy to maintain. At an aerotowing event, its very common for the tow plane to take-off and land 200-300 times over the weekend. When a plane gets that much use, and is depended on to launch scale gliders all day long, it needs to be reliable.

The Hempel Decathlon is a fantastic plane. The size is impressive and the flight characteristics superb.

Off we go.

The order was placed with Bill, http://billhempel.com/decathlon/index.php

and a week later the plane is sitting in my shop. (Expect a big box)

First out of the box is the giant fuselage. Most of the modifications are done to the fuse, so we'll just get right into it.

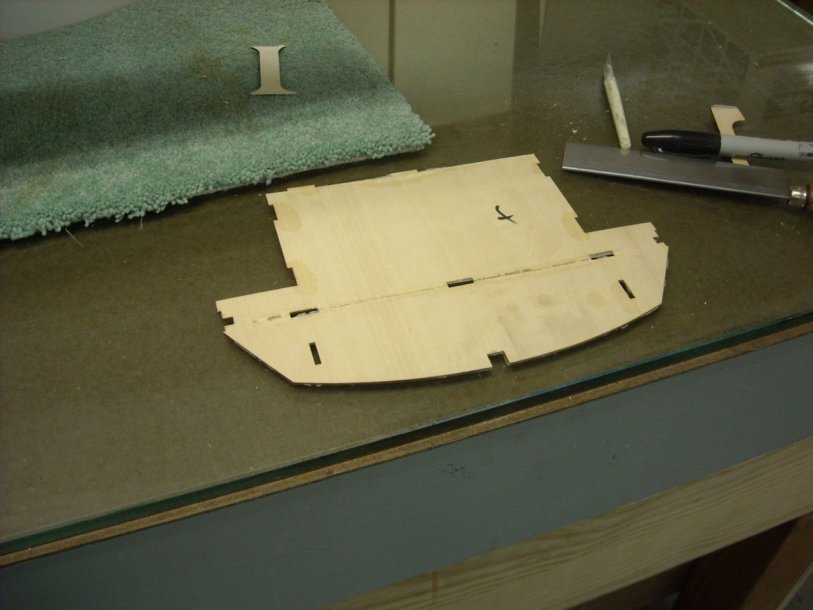

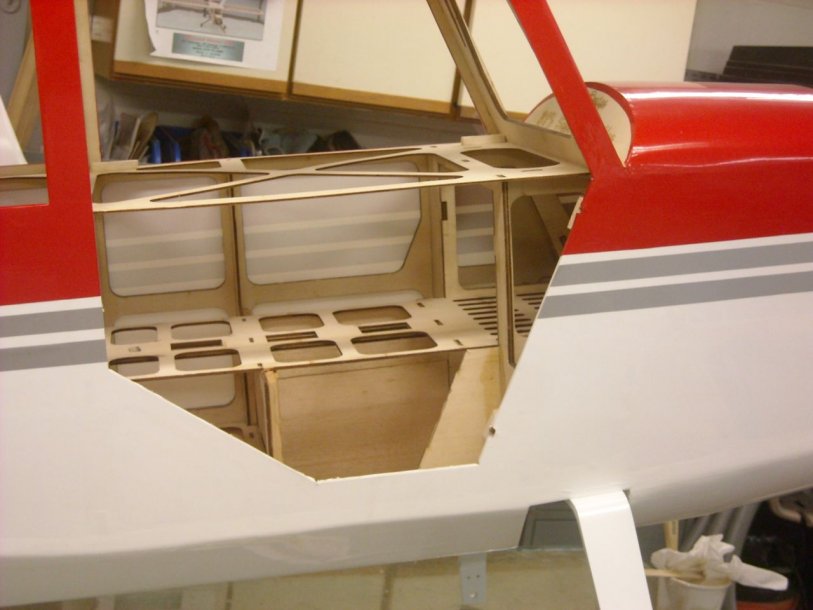

I'm mounting a DA 150 on the nose and therefore it only required shimming the motor off the firewall to get spinner clearance. Because the plane is really set up for a 120cc motor, the canister tunnel is too short.

Opening the tunnel is simply a matter of cutting and removing the rear cover from inside the door, extend the

sides of the tunnel and installing a new rear cover. I made the side removable so I can access that end of the setup.

I'm new to this site and thought I'd share with you some modification we've done to the Hempel 38% Decathlon over the last few years.

We use the Decathlon as a front line tug for aerotowing, (www.RcAerotowing.com/forum) and most of the modifications were done to make the plane ultra reliable and easy to maintain. At an aerotowing event, its very common for the tow plane to take-off and land 200-300 times over the weekend. When a plane gets that much use, and is depended on to launch scale gliders all day long, it needs to be reliable.

The Hempel Decathlon is a fantastic plane. The size is impressive and the flight characteristics superb.

Off we go.

The order was placed with Bill, http://billhempel.com/decathlon/index.php

and a week later the plane is sitting in my shop. (Expect a big box)

First out of the box is the giant fuselage. Most of the modifications are done to the fuse, so we'll just get right into it.

I'm mounting a DA 150 on the nose and therefore it only required shimming the motor off the firewall to get spinner clearance. Because the plane is really set up for a 120cc motor, the canister tunnel is too short.

Opening the tunnel is simply a matter of cutting and removing the rear cover from inside the door, extend the

sides of the tunnel and installing a new rear cover. I made the side removable so I can access that end of the setup.