3dmike

640cc Uber Pimp

This is a press release from Feetech that I received this week and it begs the question, will these find their way into our planes, heli's etc.... I think so, but not in the near future as it's got a long way to go but it shows the flexibility we may have in our future.

Check it out as it's an interesting read.

Feetech RC T-SCServo 15kg Smart Control Servo ( Controlled By Arduino)

FT-SCServo is meaning that Smart Control Servo was R&D and manufactured by FEETECH.

SCServo can work at servo mode and wheel mode.

The servo mode can be used to multi-joints robot since the robots can be controlled with specific angles. (The factory default setting is servo mode)

The wheel mode can be used to wheel-type operation robots since motors of the robots spin infinitely. (If wheel mode is available you need to program the value of position limitation the both are 0.)

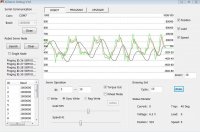

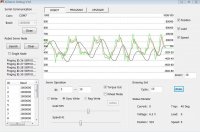

If you want to reprogram servo, you need to download the PC software (SCServo_Debug), and to connect SCPC-2(Serial Control Programming Card) between servo and PC.

More about SCServo_Debug and SCPC-2 introduce please reference its instructions.

SCServo has a unique ID number to identify on BUS network.

The range from 0 to 253 (0xFD) can be used (The factory default setting is ID 1), and, especially, 254(0xFE) is used as the Broadcast ID. If the Broadcast ID is used to transmit Instruction Packet, we can command to all SCServo.

After programmed servo ID, to be best way is written it on the sticker of servo. If not, maybe you will forget the ID when you programmed many servos.

SCServo have kinds of baud rate available.

The baud rate from 38400 bps to 1M bps can be used.

They are 38400, 57600,76800,115200,128000,250000,500000,1000000. (The factory default setting is 1000000 bps)

SCServo can feedback the value of Position, Temperature, Load, Speed and Input Voltage.

Also we can reprogram the speed of rotation, the max output torque, operating voltage limit, and operating temperature limit etc.

SCServo is easy to be controlled by Arduino.

SCServo needs to have a TTLinker connect to between Arduino and SCServo.

If not please reference Connection to UART.

TTLinker is a signal conversion board. Arduino needs to convert its UART signals to the half duplex type and through TTLinker connect to SCServo. Also TTLinker have more interface used to kinds of sensor and compatible with Arduino.

Arduino library SCServo

We have SCServo library to be used when you are using Arduino to control SCServo. You can download it from website of feetechrc.com.

For example Arduino code as shown below.

#include <SCServo.h>

SCServo SERVO;

void setup()

{

Serial.begin(1000000);//init Serial baudrate

delay(500);

SERVO.EnableTorque(0xfe,1);

}

void loop()

{

u16 i;

for(i = 0;i < 1024; i++)

{

SERVO.WritePos(0xfe,i,100);//All Servo(broadcast) rotate to the position:i

delay(10);

}

for(i = 1024; i > 0; i–)

{

SERVO.WritePos(0xfe,i,100);//All Servo(broadcast) rotate to the position:i

delay(10);

}

}

This is show that using broadcast instruction to control all of SCServo on the BUS.

About instruction of WritePos, RegWritePos, ReadPos, RegWrite, Action, SyncWritePos and more introduce instruction please reference its instructions on website of feetechrc.com.

Half Duplex Asynchronous Communication

Half duplex UART is a serial communication protocol where both TxD and RxD can’t be used at the same time. This method is generally used when many devices need to be connected to a single bus. Since more than one device is connected to the same bus, all the other devices need to be in input mode while one device is transmitting.

The Main Controller that controllers of the SCServo actuators sets the communication direction to input mode, and only when it is transmitting an Instruction Packet, it changes the direction to output mode.

Connection to UART

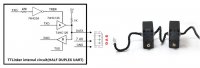

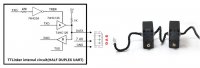

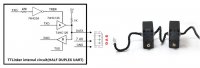

To control the SCServo actuators, the main controller needs to convert its UART signals to the half duplex type. The recommended circuit diagram for this is shown below.

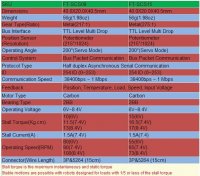

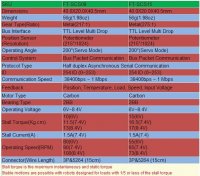

Hardware Specifications

SKU: FT-SCS15

Dimensions: 40.0X20.0X40.5mm

Weight: 56g(1.98oz)

Gear Type(Ratio): Metal(275:1)

Bus Interface: TTL Level Multi Drop

Position Sensor(Resolution): Potentiometer (215°/1024)

Operating Angle: 200°(Servo Mode)

Control System: Bus Packet Communication

Protocol Type Half duplex Asynchronous Serial Communication

ID: 254 ID (0~253)

Communication Speed: 38400bps ~ 1 Mbps

Feedback Position, Temperature, Load, Speed, Input Voltage

Motor Type: Carbon

Bearing Type: 2BB

Operating Voltage: 6V~8.4V

Stall Torque(Kg.cm): 15(6V)

16.5(7.4V)

17(8.4V)

Stall Current(A) : 1.5A(7.4)

Operating Speed(RPM): 55(6V) 65(7.4V) 73(8.4V)

Connector(Wire Length): 3P&5264 (15cm)

Stall torque is the maximum instantaneous and static torque

Stable motions are possible with robots designed for loads with 1/5 or less of the stall torque

Current application/example:

Fully programmable:

Check it out as it's an interesting read.

Feetech RC T-SCServo 15kg Smart Control Servo ( Controlled By Arduino)

FT-SCServo is meaning that Smart Control Servo was R&D and manufactured by FEETECH.

SCServo can work at servo mode and wheel mode.

The servo mode can be used to multi-joints robot since the robots can be controlled with specific angles. (The factory default setting is servo mode)

The wheel mode can be used to wheel-type operation robots since motors of the robots spin infinitely. (If wheel mode is available you need to program the value of position limitation the both are 0.)

If you want to reprogram servo, you need to download the PC software (SCServo_Debug), and to connect SCPC-2(Serial Control Programming Card) between servo and PC.

More about SCServo_Debug and SCPC-2 introduce please reference its instructions.

SCServo has a unique ID number to identify on BUS network.

The range from 0 to 253 (0xFD) can be used (The factory default setting is ID 1), and, especially, 254(0xFE) is used as the Broadcast ID. If the Broadcast ID is used to transmit Instruction Packet, we can command to all SCServo.

After programmed servo ID, to be best way is written it on the sticker of servo. If not, maybe you will forget the ID when you programmed many servos.

SCServo have kinds of baud rate available.

The baud rate from 38400 bps to 1M bps can be used.

They are 38400, 57600,76800,115200,128000,250000,500000,1000000. (The factory default setting is 1000000 bps)

SCServo can feedback the value of Position, Temperature, Load, Speed and Input Voltage.

Also we can reprogram the speed of rotation, the max output torque, operating voltage limit, and operating temperature limit etc.

SCServo is easy to be controlled by Arduino.

SCServo needs to have a TTLinker connect to between Arduino and SCServo.

If not please reference Connection to UART.

TTLinker is a signal conversion board. Arduino needs to convert its UART signals to the half duplex type and through TTLinker connect to SCServo. Also TTLinker have more interface used to kinds of sensor and compatible with Arduino.

Arduino library SCServo

We have SCServo library to be used when you are using Arduino to control SCServo. You can download it from website of feetechrc.com.

For example Arduino code as shown below.

#include <SCServo.h>

SCServo SERVO;

void setup()

{

Serial.begin(1000000);//init Serial baudrate

delay(500);

SERVO.EnableTorque(0xfe,1);

}

void loop()

{

u16 i;

for(i = 0;i < 1024; i++)

{

SERVO.WritePos(0xfe,i,100);//All Servo(broadcast) rotate to the position:i

delay(10);

}

for(i = 1024; i > 0; i–)

{

SERVO.WritePos(0xfe,i,100);//All Servo(broadcast) rotate to the position:i

delay(10);

}

}

This is show that using broadcast instruction to control all of SCServo on the BUS.

About instruction of WritePos, RegWritePos, ReadPos, RegWrite, Action, SyncWritePos and more introduce instruction please reference its instructions on website of feetechrc.com.

Half Duplex Asynchronous Communication

Half duplex UART is a serial communication protocol where both TxD and RxD can’t be used at the same time. This method is generally used when many devices need to be connected to a single bus. Since more than one device is connected to the same bus, all the other devices need to be in input mode while one device is transmitting.

The Main Controller that controllers of the SCServo actuators sets the communication direction to input mode, and only when it is transmitting an Instruction Packet, it changes the direction to output mode.

Connection to UART

To control the SCServo actuators, the main controller needs to convert its UART signals to the half duplex type. The recommended circuit diagram for this is shown below.

Hardware Specifications

SKU: FT-SCS15

Dimensions: 40.0X20.0X40.5mm

Weight: 56g(1.98oz)

Gear Type(Ratio): Metal(275:1)

Bus Interface: TTL Level Multi Drop

Position Sensor(Resolution): Potentiometer (215°/1024)

Operating Angle: 200°(Servo Mode)

Control System: Bus Packet Communication

Protocol Type Half duplex Asynchronous Serial Communication

ID: 254 ID (0~253)

Communication Speed: 38400bps ~ 1 Mbps

Feedback Position, Temperature, Load, Speed, Input Voltage

Motor Type: Carbon

Bearing Type: 2BB

Operating Voltage: 6V~8.4V

Stall Torque(Kg.cm): 15(6V)

16.5(7.4V)

17(8.4V)

Stall Current(A) : 1.5A(7.4)

Operating Speed(RPM): 55(6V) 65(7.4V) 73(8.4V)

Connector(Wire Length): 3P&5264 (15cm)

Stall torque is the maximum instantaneous and static torque

Stable motions are possible with robots designed for loads with 1/5 or less of the stall torque

Current application/example:

Fully programmable: