GSNadmin

Staff member

EASY-INSTALL EYELETS

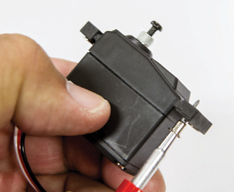

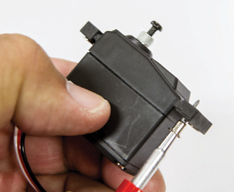

The brass eyelets that come with rubber servo grommets are often a tight fit, and they can be tiresome to install by hand. A handy alternative is to use a punch or a piercer to apply them. Mount the grommet on the servo, and slip the eyelet over the tip of the punch. Then use the leverage of the punch to pop the eyelet into place. When you want to remove it, just insert the punch from the top. Be careful not to get your other hand in the way of the tip, and be sure to brace the servo on its casing rather than on the output gear to avoid damaging the servos by putting pressure on them.

A HELPING HAND

It can be challenging to install small screws in tight places. Instead of clumsy fingers in a slender fuselage, a great way to hold and guide small parts is with curved-tip tweezers. For maximum versatility, the tweezers’ tip should be rounded and as close to 90 degrees as possible. Also use the tweezers to grip small parts to avoid losing them as you remove them from tight spots.

SHARP IDEA FOR HOBBY KNIVES

Never again endure the pain of a hobby knife falling blade-first onto your foot! Attach a common zip-tie to the handle of your blade, and it will stay safely on your tabletop. If your hobby knife handles are identical, use different color zip-ties to designate different degrees of blade sharpness. For example, use a red zip-tie to indicate a new blade for precise trimming and a white zip-tie to indicate a knife with a used blade for general cutting.

CUT-RATE COVER CUTTERS

A scroll-shaped letter opener makes a surprisingly effective tool for cutting airplane covering material. The slot in the bottom feeds the material in flat for a smooth cut. The cutters are sharp enough to slice the covering without hanging or snagging on it, and the handle makes it easy to cut in one long, smooth motion. Best of all, lots of businesses use these letter openers as advertising, so you can probably collect a few without spending a dime.

SHORTY SCREWDRIVER

Sometimes it’s tough to get a conventional-size screwdriver into tight places. Try inserting a bit from a cordless screwdriver into a box wrench to deal with fasteners in cramped locations.

SOAP YOUR SCREWS

Wood screws don’t always thread in as effortlessly as we’d like; it can be hard on your hands and the model. Next time, try swiping the screw’s threads across a damp or dry bar of soap. The soap acts as a lubricant, making it much easier to thread the screw in. It is particularly useful in tight areas where it is difficult to get a good grip on tools.

WIRE WRANGLING

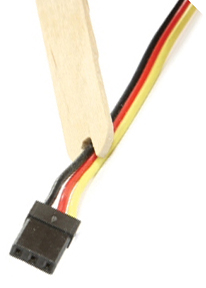

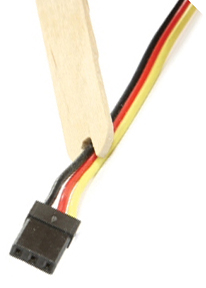

The space inside the radio compartments of some of today’s small park flyers is very tight, and that makes it difficult to arrange servo leads, battery and motor wires. To move wires where your fingers can’t reach, cut a notch of the appropriate size and shape for your wires in the end of a Popsicle stick. Hook the wires in the notch, and use the stick to push them back into the fuselage where they won’t be in the way.

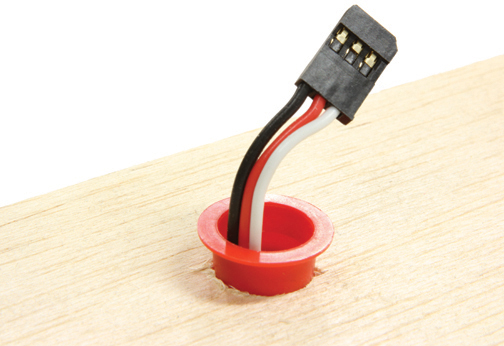

SECURING SERVO WIRES

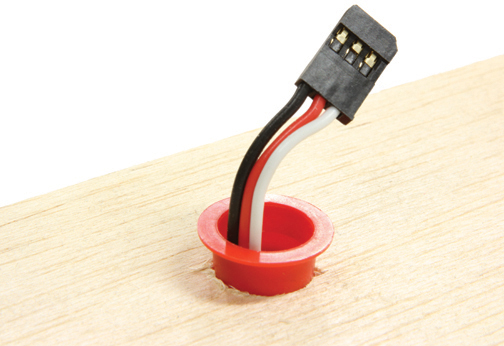

At one time or another, most of us have had to fish for a servo extension wire that slipped back inside the wing; but there is a solution. Cut a 3/16-inch hole in the bottom of the red plug from an old bottle of epoxy. Across the hole, cut a slot that’s just wide enough to squeeze the connector at the end of your servo extension through. Trim the access hole in the wing to fit the plug, and you’ll never have to go fishing again. This trick also works well for hold-down bolts.

Model Airplane News - The #1 resource for RC plane and helicopter enthusiasts featuring news, videos, product releases and tech tips.

Continue reading...

The brass eyelets that come with rubber servo grommets are often a tight fit, and they can be tiresome to install by hand. A handy alternative is to use a punch or a piercer to apply them. Mount the grommet on the servo, and slip the eyelet over the tip of the punch. Then use the leverage of the punch to pop the eyelet into place. When you want to remove it, just insert the punch from the top. Be careful not to get your other hand in the way of the tip, and be sure to brace the servo on its casing rather than on the output gear to avoid damaging the servos by putting pressure on them.

A HELPING HAND

It can be challenging to install small screws in tight places. Instead of clumsy fingers in a slender fuselage, a great way to hold and guide small parts is with curved-tip tweezers. For maximum versatility, the tweezers’ tip should be rounded and as close to 90 degrees as possible. Also use the tweezers to grip small parts to avoid losing them as you remove them from tight spots.

SHARP IDEA FOR HOBBY KNIVES

Never again endure the pain of a hobby knife falling blade-first onto your foot! Attach a common zip-tie to the handle of your blade, and it will stay safely on your tabletop. If your hobby knife handles are identical, use different color zip-ties to designate different degrees of blade sharpness. For example, use a red zip-tie to indicate a new blade for precise trimming and a white zip-tie to indicate a knife with a used blade for general cutting.

CUT-RATE COVER CUTTERS

A scroll-shaped letter opener makes a surprisingly effective tool for cutting airplane covering material. The slot in the bottom feeds the material in flat for a smooth cut. The cutters are sharp enough to slice the covering without hanging or snagging on it, and the handle makes it easy to cut in one long, smooth motion. Best of all, lots of businesses use these letter openers as advertising, so you can probably collect a few without spending a dime.

SHORTY SCREWDRIVER

Sometimes it’s tough to get a conventional-size screwdriver into tight places. Try inserting a bit from a cordless screwdriver into a box wrench to deal with fasteners in cramped locations.

SOAP YOUR SCREWS

Wood screws don’t always thread in as effortlessly as we’d like; it can be hard on your hands and the model. Next time, try swiping the screw’s threads across a damp or dry bar of soap. The soap acts as a lubricant, making it much easier to thread the screw in. It is particularly useful in tight areas where it is difficult to get a good grip on tools.

WIRE WRANGLING

The space inside the radio compartments of some of today’s small park flyers is very tight, and that makes it difficult to arrange servo leads, battery and motor wires. To move wires where your fingers can’t reach, cut a notch of the appropriate size and shape for your wires in the end of a Popsicle stick. Hook the wires in the notch, and use the stick to push them back into the fuselage where they won’t be in the way.

SECURING SERVO WIRES

At one time or another, most of us have had to fish for a servo extension wire that slipped back inside the wing; but there is a solution. Cut a 3/16-inch hole in the bottom of the red plug from an old bottle of epoxy. Across the hole, cut a slot that’s just wide enough to squeeze the connector at the end of your servo extension through. Trim the access hole in the wing to fit the plug, and you’ll never have to go fishing again. This trick also works well for hold-down bolts.

Model Airplane News - The #1 resource for RC plane and helicopter enthusiasts featuring news, videos, product releases and tech tips.

Continue reading...