stangflyer

I like 'em "BIG"!

Ok...so this is actually an easy fix. The problem is not your servos, the speeds or anything related. That is unless you are using two different type servos for Ailerons, two different for elevators, etc. As long as you use the "same" servo for each control surface, (i.e., 1268's on "BOTH" elevator halves, etc.) your end result will be matching movement on the surfaces. The problem you are having is that you are "MIXING" a program to (2) servos with a "condition" on your transmitter. Hence, you are getting two separate values for the two separate servos. I also use "Smart-Fly" power expanders. In my opinion, they are so darned easy to use and offer such a great deal of insurance with redundancy. What I do to set these up is to use two separate channels for my Ailerons, Two separate channels for my elevators, two separate channels for the rudder as well, and then set the values for each control surface. The two separate rudder will not apply in this case as you are using (1) rudder servo so you will only use one rudder channel. Therefore when you set your dual rates, the amount of throw for all surfaces remain what your initial value is for your high rates, your low rates are reduced and determined by what you set for your dual rate and expo values. Make sense? I use this setup on all my 100cc to my largest ships. By running separate channels for each control surface, you get the best accuracy of tuning...Plus you are also adding in a redundancy for safety. In the event...(Hypothetical situation) You lose your left aileron for some really odd reason.... you are not depending on that channel to control your right aileron. Case in point that "ACTUALLY" did in fact happen to me last weekend with my 129" 40% Yak. Situation. My son helped me set the Yak up for flying that day when we arrived to the field. He and I use the same setups basically and even the same hardware from different vendors like @Taildragger RC. So, he plugged my wings in...(Using the Multiplex harness), then plugs my stabs in. I bolt everything down, fuel up and fly two really good flights. He leaves for home and I put one more flight on the Yak. Upon doing an aileron roll, I noticed the Yak just "DID NOT" roll at the normal rate. I immediately landed and discovered that my left aileron driven by three servos on that wing had absolutely no functional operation. I brought the plane around for a very uneventful set up and touch down. Every thing "seemed" fine. Now why the harness came disconnected is a mystery, as my son is "VERY" astute and rarely makes a mistake. Either way, I flew the plane to safety and touch down on one aileron. Now I also understand that had I been using just one channel for the ailerons, the end result would still have been the same with an unplugged harness. But the point is, by running separate channels for each half of your control surface, you can fine tune to "Equal" values each control surface and also have redundancy safety in the event you loose a flight control channel in flight. A side note to keep in mind, I am doing this with a simple 9 channel receiver and only utilizing 7 of those 9 channels. It is a "very" easy setup with the least amount of stress in setting up. I hope this helps and didn't confuse you too much.Hi guys!

Although I am new to this forum I have been following this build for quite a while. I must give a big thank you for the details you share. Especially to Joe hunt for the vids about programming. So helpful! however I am still struggling to figure everything out.

Anyway, I am about to finish a Pilot Extra 107". I will post some pics tomorrow to show what I have done so far.

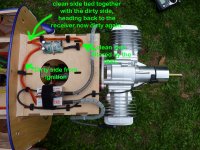

Quick details : engine DLE111 with MTW mufflers. I have 2 savox 1268 per wing, 2 savox 1268 on the elevator, 1 savox 2230 on the rudder and one MKS on throttle. I also use a Smartfly EQ10 with a 14 channels Futaba receiver, 2 Pulse batteries ( 3600mah) and a Ultra Ibec.

When you will see the pictures, could you tell me if I need to modify something? My biggest concern is about the rudder system : you will see a giant arm which helps keeping the wires ( pull-pull system) from loosening. I am not quite sure one servo will be enough...

One question : The EQ10 is so easy to use! I love it. So, I programmed all my servos. I wanted to check if my elevator was working properly. I have programmed my end points and center, on high rates, accurately. However, when I switch to low rate ( I do it with a condition setting on my Futaba programmer), I notice that there is a small difference between the two sides of the elevator. I also notice that one servo goes slightly faster than the other one. I tried to fix the problem while changing the length of the pushrod, but it does nothing spectacular.. I guess the problem comes from that the two 1268 servos are not exactly the same and I should change the speed of one. I have a "speed" menu in my transmiter, maybe it is the way to go?

I don't think I will notice something when the Extra will be in the air, but I would like to understand if I could improve my settings. Could you help me with that?

thanks a lot

Last edited: