TonyHallo

150cc

The manual doesn't suggest a specific length, just route to bottom of the plane.

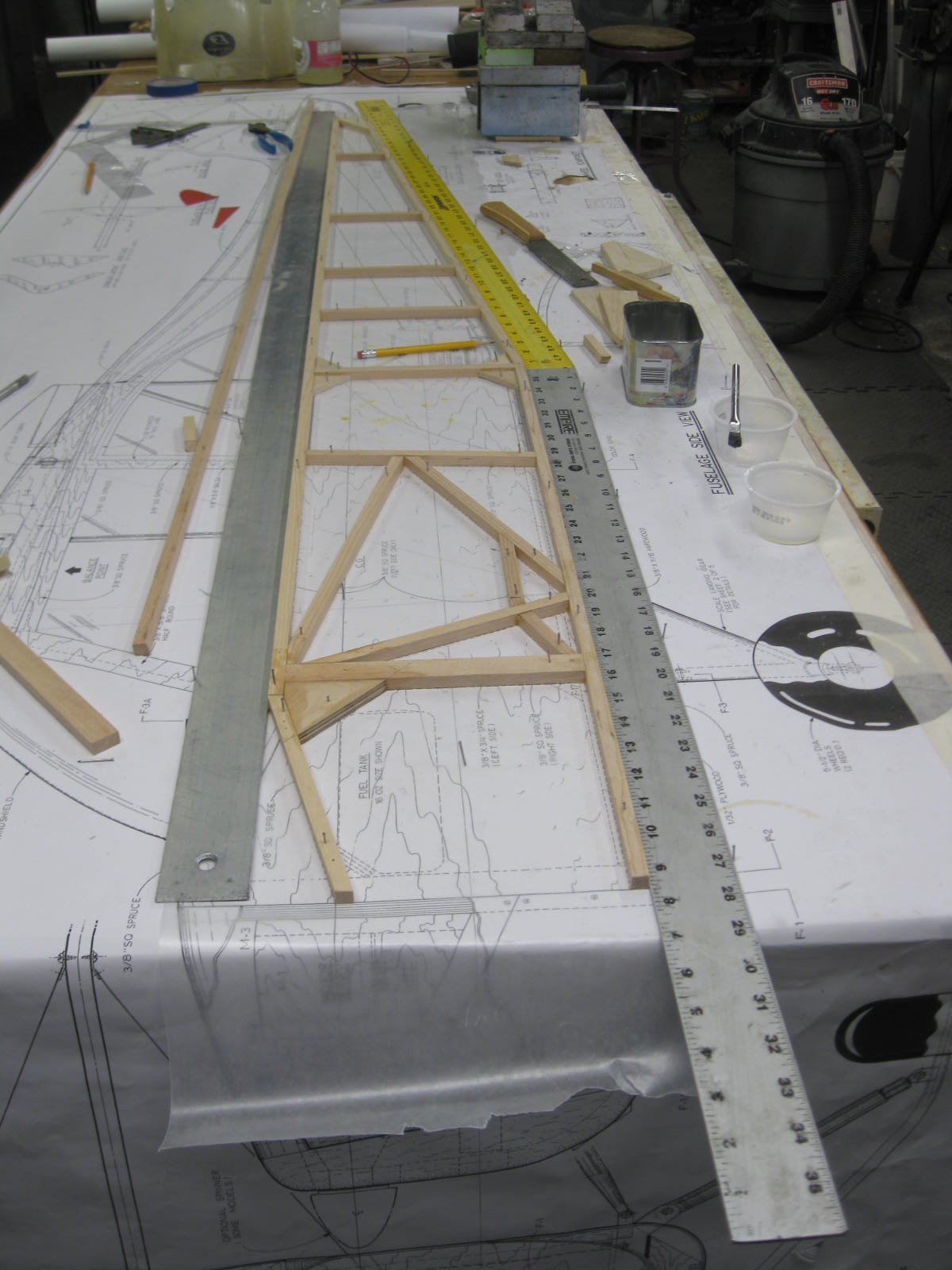

Got the left side off the bench. Been thinking about the sharp break on the lower longeron, the plans indicate a butt joint with two 1/4" balsa gussets on each side. Simulated a bend once the side removed and of course as one might expect, the butt glue joint failed. I cut equally on each side of the butt joint and spliced a lap joint greater than 10 to 1. It is pinned back down while the glue is drying.

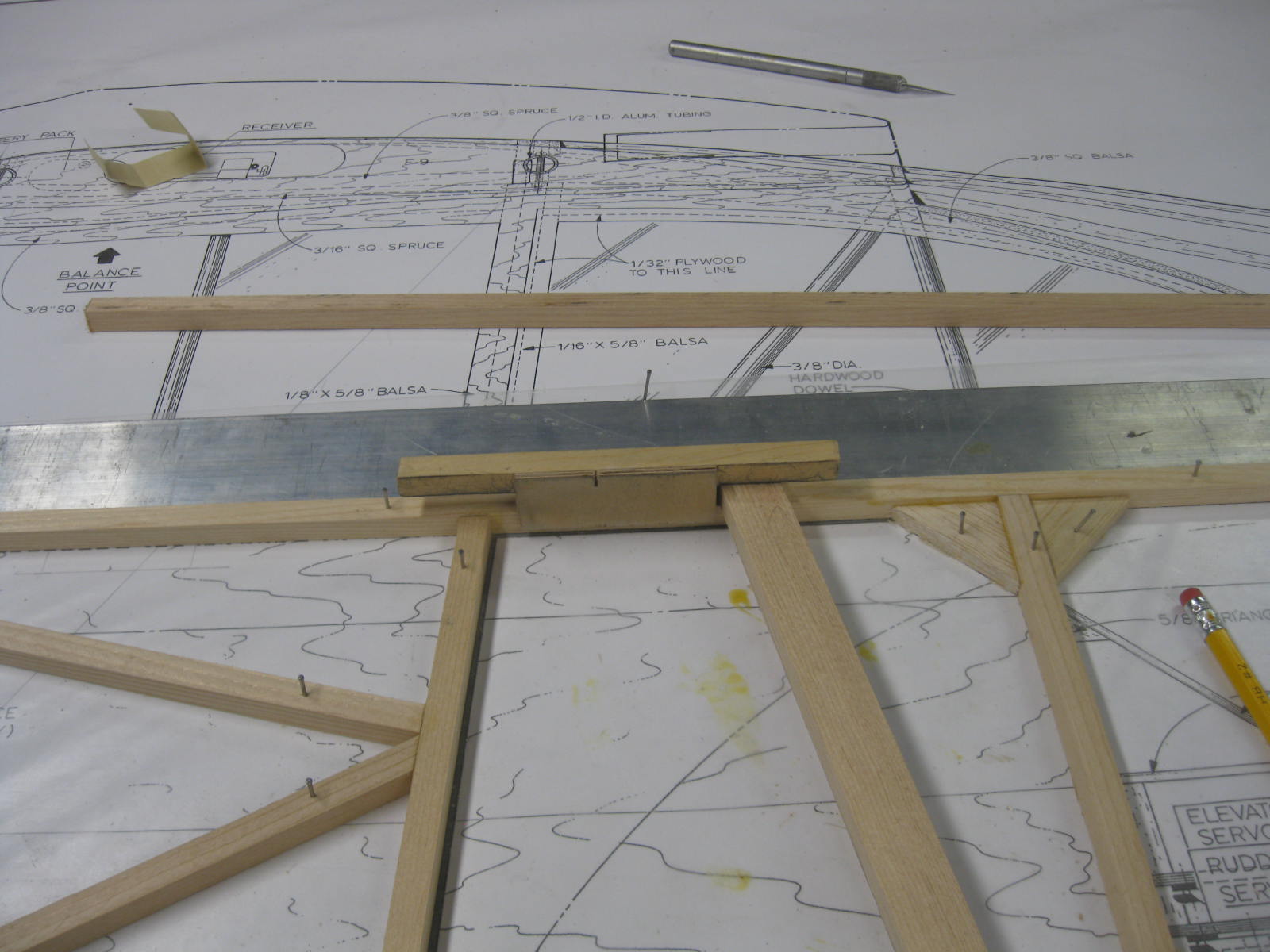

I use this tool made from scrap to mark the cut lines on the pieces filled in between the upper and lower longerons, hold the stock over the plan on top of the longerons at the desired angle, butt the tool against the longeron and give it a mark.

Got the left side off the bench. Been thinking about the sharp break on the lower longeron, the plans indicate a butt joint with two 1/4" balsa gussets on each side. Simulated a bend once the side removed and of course as one might expect, the butt glue joint failed. I cut equally on each side of the butt joint and spliced a lap joint greater than 10 to 1. It is pinned back down while the glue is drying.

I use this tool made from scrap to mark the cut lines on the pieces filled in between the upper and lower longerons, hold the stock over the plan on top of the longerons at the desired angle, butt the tool against the longeron and give it a mark.