Snoopy1

640cc Uber Pimp

Hey Fellas; I guess I am stuck at home today due to really "WET" weather. Ugh.. At least it is warm. Right at about 50 degrees and loving it. Spring will be here sooner than we think. Maybe I can get a few irons out of the fire today and maybe get a few things caught up. Got off yesterday at 2 so I decided I would get the ball rolling with that pesky broken muffler on the Baby Yak-Ster. I should have done this in the first place. I stalled for a long time trying to decide whether or not to cut the cowl for the stock muffler.

I hope I don't go overboard with all the information. As usual, I try to include as much information as possible to help some of the newer guys to the hobby. Most all of you fellas already know this stuff.

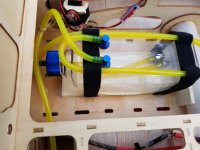

First, off with the spinner, prop and cowl. Nice to see things just as they were when I put the cowl on. Nice and clean and organized.

View attachment 101255

Well except for this....!!! Ugh!!!

View attachment 101256 View attachment 101257 View attachment 101258

Goofy as it may be, apparently the aluminum muffler just was too weak at the flange joint. Oh well, we're gonna rectify this. First though, a quick looksy at the double ringed piston. Clean and well lubed. Gotta love that Redline.

View attachment 101259

Also took a minute to double check the torque on all mounting hardware and bolts.

View attachment 101260 View attachment 101261

Ok, on to the header and canister install. First, a little clean up of the mounting flange on the DA 60 flex header with a flat file. Just making sure the surface is clean.

View attachment 101262

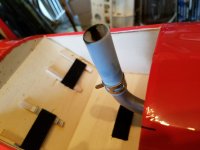

This is the intended replacement exhaust setup. DA 60 Flex Header and KS 60 canister. I may have to go to an MTW 75 for better flow, but I am going to try the KS 60 first.

View attachment 101263

The first and only real hurdle in this setup is going to be the header mounting flange. The bend of the header as it exits the flange is just too sharp of a bend that it is next to impossible to get a bolt in there. Perhaps this is why the gent I bought the nearly new header from sold it so inexpensively? At any rate, even the shortest bolt I have is difficult to get in the flange. And even that will not facilitate inserting a hex wrench to tighten it. Not to mention, just way too few threads to feel comfortable with. I certainly don't want to strip the cylinder threads out.

View attachment 101264 View attachment 101265 View attachment 101266 View attachment 101267

Have to take a minute and attend to something. Back in few minutes with more of this header and canister install.

Why would you not put a stud in the cylinder head and then use a nut to tighten it down.