You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

IMAC The new Dalton 300 SP / 330

- Thread starter orthobird

- Start date

great news, many of the other things I needed for the kit has arrived:

additionally, the wing tube and phenolic has arrived.

Now, I can proceed to make the wings! Yippie!

Here, is where I have to make every effort to make this model not get to the 46 pound range. I wonder what weight Tom Wheeler will get with his.

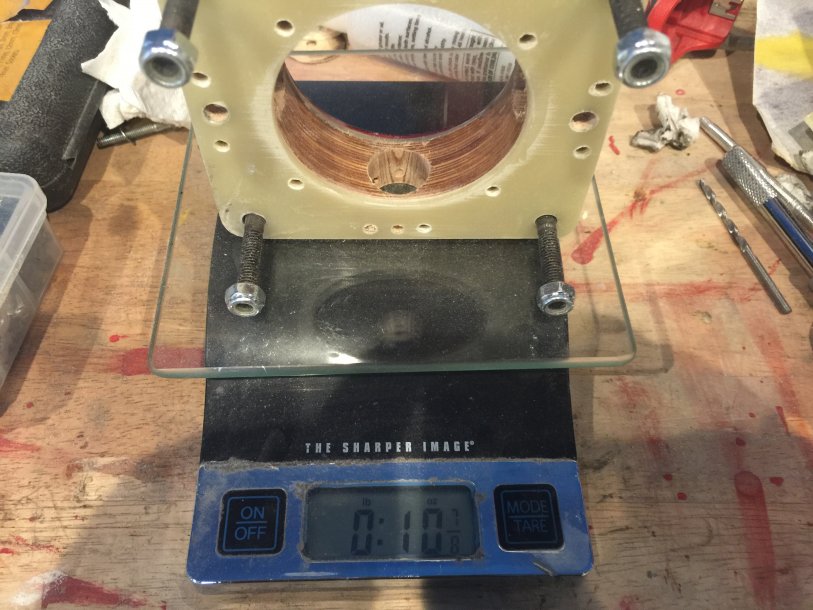

Mine, will have the 200 L, which weighs 9 pounds and 15 ounces, and with two sets of canisters and headers and the mounts, it adds an additional 2 pounds. SO that will be around 12 pounds or so, in that alone. (motor + canister + header). being that I need a motor mount extension, I want to make that as light as possible. Here is the original mount I made...

this one weighs 11 ounces and 3/8.

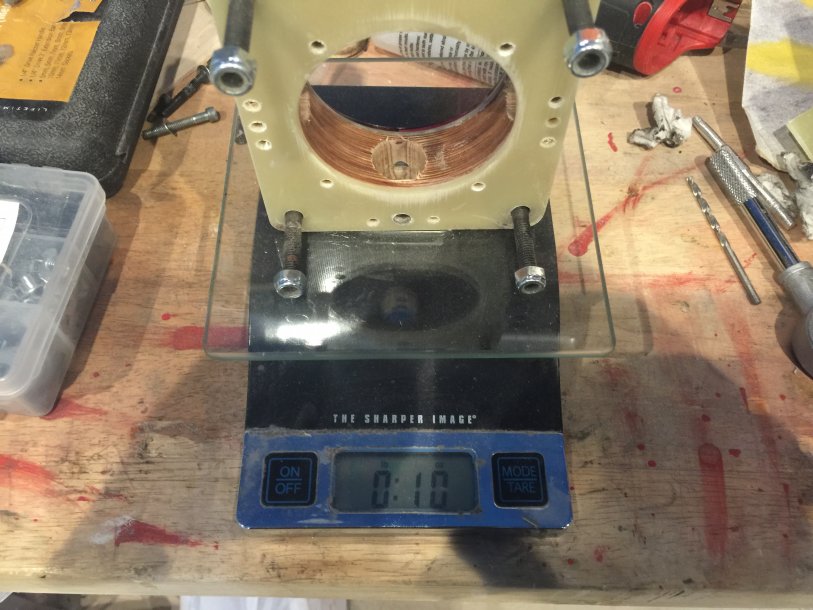

What I did is cut out holes on the sides of it, and was able to shed over 1 once off....

this is after making 4 holes, one on each side... 10 and 7/8 ounce.

this is after there are now 3 holes on each side, total of 12 holes cut out...

10 ounces even.

In all my other Dalton builds (5 pairs of wings) , I have used poly-urethane glue, and measured and used, a total of 6 ounces of poly-urethane glue per side, for a total of 24 ounces . 24 ounces is glue alone! Not good. that is 1.5 pounds in the wings for the glue.

Now that I have the vacuum bag equipment, I will attempt to bag the wings, and use maybe 2 to 3 ounces total per side. this would be, at most, 12 ounces, and maybe even 8 ounces, total, of glue, on the wings. I will use epoxy resin.

I want to add, I have ordered titanium bolts, 6 mm by 75 mm for the motor mount. This will replace the current stainless steel SCHS. BY doing so, the weight reduction will be 1/2 of the original weight. The 4 titanium bolts, + washers + the nuts, was about 110 dollars. I know, sounds crazy, but I would really like to build a model that weighs under 42 pounds. It is my dream!!

I also have ordered aluminum 6-32 screws for the hatch, stab mounts, and cowl mounts. the aluminum will weigh 1/3 the weight of the steel or alloy screws.

Wish me luck.

additionally, the wing tube and phenolic has arrived.

Now, I can proceed to make the wings! Yippie!

Here, is where I have to make every effort to make this model not get to the 46 pound range. I wonder what weight Tom Wheeler will get with his.

Mine, will have the 200 L, which weighs 9 pounds and 15 ounces, and with two sets of canisters and headers and the mounts, it adds an additional 2 pounds. SO that will be around 12 pounds or so, in that alone. (motor + canister + header). being that I need a motor mount extension, I want to make that as light as possible. Here is the original mount I made...

this one weighs 11 ounces and 3/8.

What I did is cut out holes on the sides of it, and was able to shed over 1 once off....

this is after making 4 holes, one on each side... 10 and 7/8 ounce.

this is after there are now 3 holes on each side, total of 12 holes cut out...

10 ounces even.

In all my other Dalton builds (5 pairs of wings) , I have used poly-urethane glue, and measured and used, a total of 6 ounces of poly-urethane glue per side, for a total of 24 ounces . 24 ounces is glue alone! Not good. that is 1.5 pounds in the wings for the glue.

Now that I have the vacuum bag equipment, I will attempt to bag the wings, and use maybe 2 to 3 ounces total per side. this would be, at most, 12 ounces, and maybe even 8 ounces, total, of glue, on the wings. I will use epoxy resin.

I want to add, I have ordered titanium bolts, 6 mm by 75 mm for the motor mount. This will replace the current stainless steel SCHS. BY doing so, the weight reduction will be 1/2 of the original weight. The 4 titanium bolts, + washers + the nuts, was about 110 dollars. I know, sounds crazy, but I would really like to build a model that weighs under 42 pounds. It is my dream!!

I also have ordered aluminum 6-32 screws for the hatch, stab mounts, and cowl mounts. the aluminum will weigh 1/3 the weight of the steel or alloy screws.

Wish me luck.

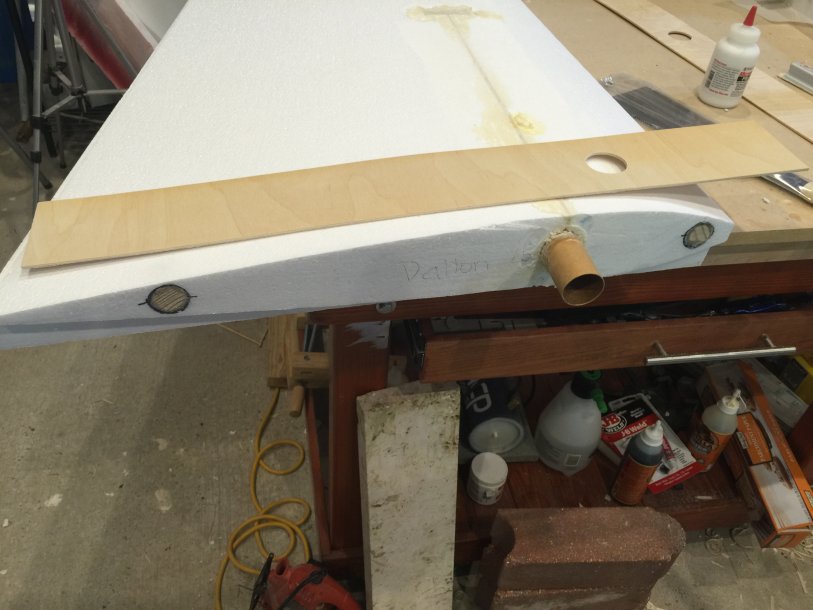

to bring everyone up to speed, I have installed the wing phenolics. Additionally, they were capped with balsa, then they were reinforced at the ends with the balsa support. I also made it, such that, i filled in gaps with balsa. I am considering whether or not to add a spar above and below, the way Wayne Mathews had told me, and I had incorporated in the last 3 sets of wings I manufactured. this is basically, a 1/4" square carbon fiber rod, from the root, and 48" length. they do not reach the tip, but not required, since there is much less loading the closer you get to the tips. Problem with this, is, that adding those will increase the weight about 4 ounces per wing. SO this has to be considered.

Additionally, Tony has sent me the new design which is a longer wing tube and deeper sockets. Therefore, I wonder If I really need to do the modifications as I had before with the upper and lower spars.

Currently< I am also building two Cardens, and on those kits, It comes with a wing tube support and extension, similar to what Wayne Mathews had told me, except, it is much shorter, and centered over the tip of the wing tube. In such a fashion, that is spans it. Maybe i can do this, and hopefully the penalty will not be significant.

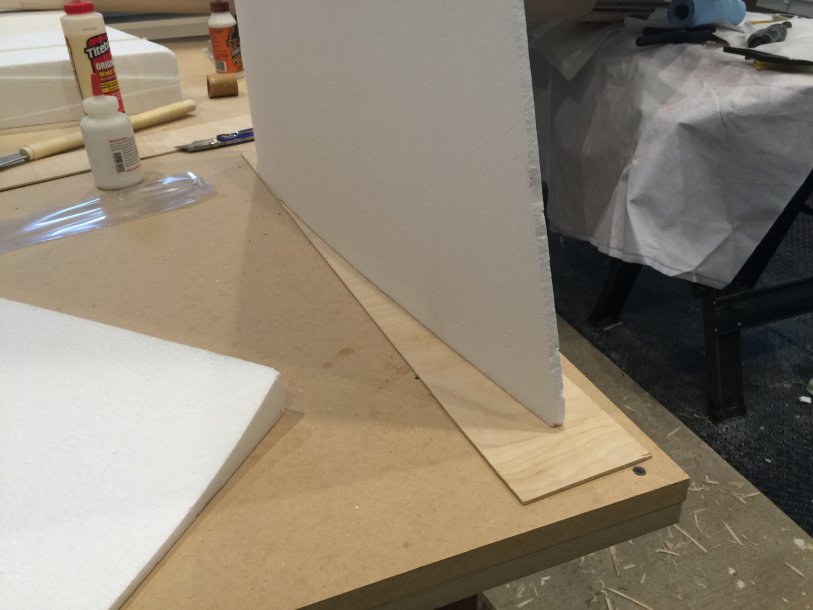

after the phenolic cured, I obtained the plywood root cap, and cut off the excess phenolic.

once I sanded it level with the root cap, then I placed the wing over the root cap, and delineated the border.

Once delineated, then I was able to trim it...

Now, I have attached the root cap to the wing, and waiting for this to cure. Then I will do the other wing, and then maybe, I can sheet one wing tonight.

Additionally, Tony has sent me the new design which is a longer wing tube and deeper sockets. Therefore, I wonder If I really need to do the modifications as I had before with the upper and lower spars.

Currently< I am also building two Cardens, and on those kits, It comes with a wing tube support and extension, similar to what Wayne Mathews had told me, except, it is much shorter, and centered over the tip of the wing tube. In such a fashion, that is spans it. Maybe i can do this, and hopefully the penalty will not be significant.

after the phenolic cured, I obtained the plywood root cap, and cut off the excess phenolic.

once I sanded it level with the root cap, then I placed the wing over the root cap, and delineated the border.

Once delineated, then I was able to trim it...

Now, I have attached the root cap to the wing, and waiting for this to cure. Then I will do the other wing, and then maybe, I can sheet one wing tonight.